Cabinet axial fans are used for cleaning polluted air which is created by humans, vehicles, or any other machines. The polluted air brought to the exit point by jet fans or ventilation ducts is taken out with the help of cabinet axial fans. The rate of toxic substance in the air is reduced and the clean air is obtained. Cabinet fans can be used in industrial buildings, parking lots, airports, tunnels, etc. Cvsair cabinet axial fans are manufactured with galvanized ( zinc ) coating. Zinc layers are oxidized more quickly than the metal layers therefore the fan metal is not damaged. This fact prevents the formation of rust and corrosion. With help of aerofoil-section blade friction forces are optimized. Blade angle is adjustable for the maximum airflow efficiency. There is a cabinet outside of the impellers to protect motor and impellers from external effects. Three-phased motors are suitable to operate with frequency invertors. Airflow starts from the motor side and finishes at the impeller side. All parts are produced according to the EN 12101-3 certificate. Highly efficient IE2 motors with Class-H insulation and IP55 protection can be designed to operate dual sided on demand. Cabinet axial fans are designed for working outside or inside with either vertical or horizontal placement. Vibration dampeners are mounted during installation process and the dampeners are also produced with connection flanges which enables to use silencer with or without pods. 60 Hz option is available. For more information about the products, please check out the presentation prepared by Cvsair.

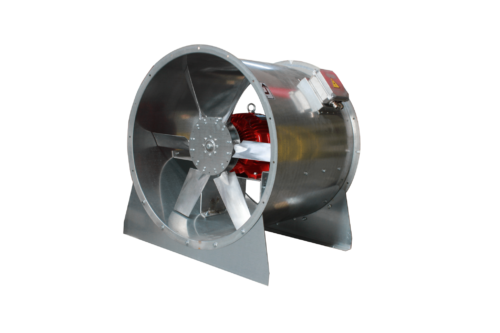

Cabinet Axial Fan

CABINET AXIAL FAN – PRODUCT FEATURES

Cabinet Axial Fan

Galvanised sheet metal with electrostatic oven dryed case

Adjustable blade angle for maximum efficiency

Three-phased motor is suitable to operate with frequency inverter

Double speed motor on demand

EN 12101-3 certified

60 Hz option is available